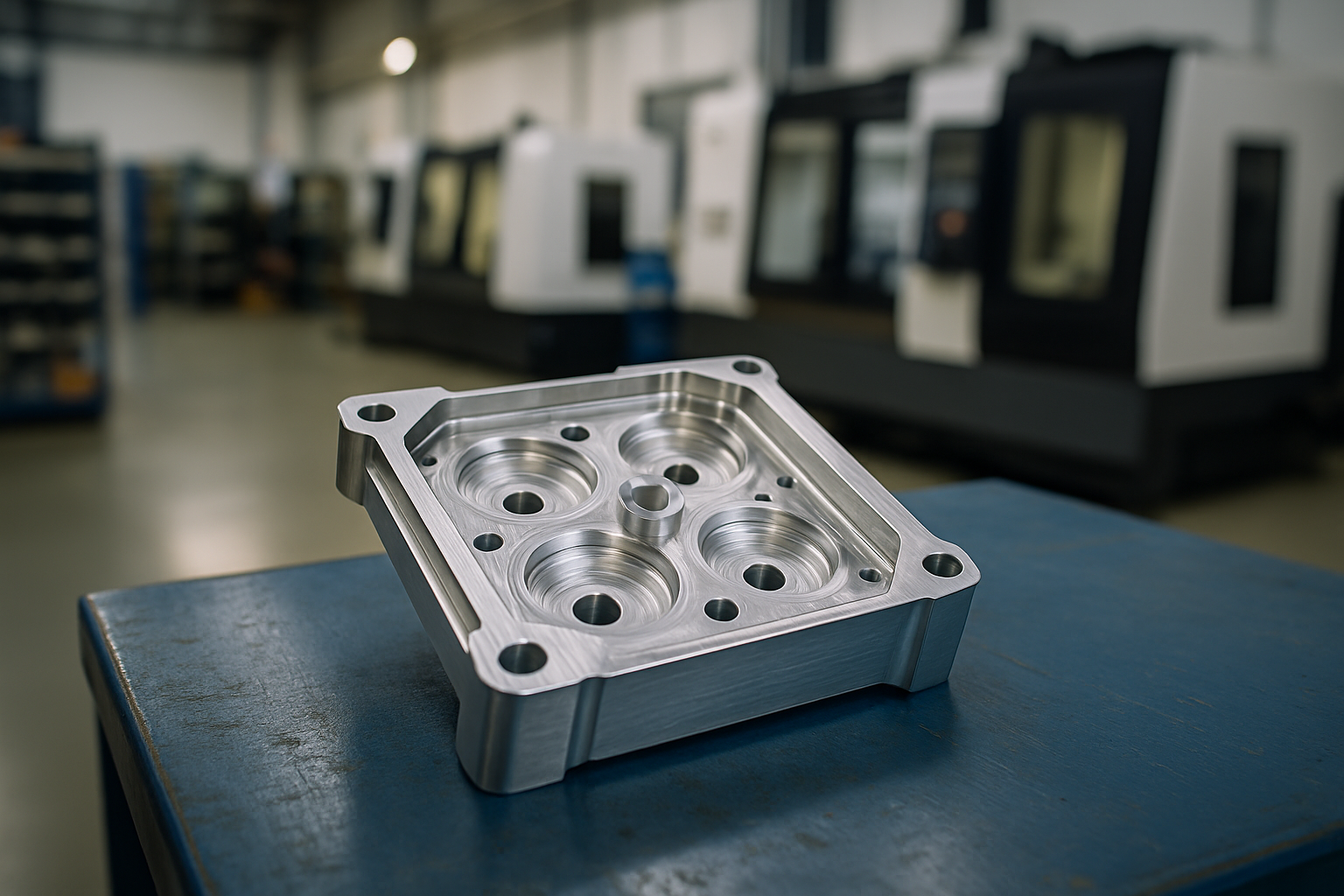

When your product demands micron-level accuracy, surface perfection, and absolute reliability, the choice of machining partner determines success or failure. At XY-GLOBAL, we specialize in machining services for components where “good enough” is never enough — from optical housings with ±1 µm tolerance to medical-grade stainless steel parts with mirror-like finishes.

Our job is simple but demanding: transform your drawings into precise, functional parts that work flawlessly in the real world.

Precision Is Not a Feature — It’s the Foundation

A component with a 0.5 mm thickness tolerance of ±0.005 mm. A titanium housing that must stay flat within 2 µm. A stainless steel fixture whose surface finish must stay below Ra 0.01 µm.

These are not exceptions in our daily work — they are standard requirements. Our machining centers, measurement systems, and process control are all built around meeting such challenges consistently. Whether the part ends up in an endoscope, a laser alignment system, or a semiconductor tool, we make sure every cut, hole, and surface meets the spec the first time.

Full Machining Capabilities, From Start to Finish

We provide a complete range of machining services to support projects from concept through production:

-

Multi-axis CNC Milling and Turning – Handles complex shapes and tight tolerances efficiently.

-

Wire EDM and EDM – For sharp internal features and ultra-precise geometries.

-

Precision Grinding and Polishing – Delivers mirror-quality surfaces and micron-level flatness.

-

Surface Treatments – Including anodizing, PVD, plating, and coating for durability and aesthetics.

All these processes are done under one roof, controlled by one team, so you get faster turnaround, consistent quality, and zero excuses.

Materials and Industries We Serve

We work with a wide range of metals and engineering plastics — aluminum, stainless steel, titanium, tool steel, PEEK, and more — to meet the demands of different industries:

-

Optics & Photonics: Precision mirror mounts, lens barrels, and alignment structures.

-

Medical Devices: Biocompatible surgical instruments, implant components, and housings.

-

Semiconductor Equipment: Ultra-clean, stable components for demanding environments.

-

Aerospace & Automotive: Lightweight, high-strength parts built for safety and performance.

Prototype to Production — Without Friction

Time is critical in product development. That’s why we offer rapid prototyping — often delivering functional parts in 1–3 days — followed by seamless transition into mass production. Whether you need 1 piece or 10,000, our flexible production system ensures consistent quality and predictable lead times.

Quality That’s Measured, Not Assumed

Every part undergoes strict inspection using CMMs, optical measurement systems, and surface testers. We provide full documentation — from material certificates to inspection reports — and comply with ISO 9001:2015 and ISO 13485:2016 standards. Traceability is built into every step of our process.

More Than Manufacturing: DFM Support That Saves You Time

Many machining challenges can be solved before production even starts. Our engineering team provides Design for Manufacturability (DFM) feedback to help refine your design for better performance, lower cost, and faster production. This proactive approach prevents costly redesigns and delays later in the project.

Why Customers Trust Our Machining Services

-

Proven ability to hold ultra-tight tolerances and superior surface quality.

-

End-to-end machining processes in-house.

-

Experience across optics, medical, semiconductor, and aerospace sectors.

-

Fast prototyping and scalable production capacity.

-

Certified quality system and complete traceability.

-

Engineering collaboration from day one.

Let’s Build Your Next Precision Component

If your project demands more than just “machined parts” — if it needs precision, reliability, and deep manufacturing expertise — we’re ready to help. Send us your drawings and requirements, and our team will deliver detailed DFM feedback and a fast quotation.

With XY-GLOBAL, complex designs become precision reality.

Kongsi:

Why Aluminum Die Casting Is the Go-To Choice for Complex Metal Parts

Top Die Casting Companies for Precision Aluminum and Zinc Parts