A gear machine shop today must deliver far more than gear cutting—it’s expected to meet the rising demand for ultra-precise components in compact assemblies, complex tooling environments, and high-performance systems. Our facility is structured around gear manufacturing as the core, yet we’ve expanded into advanced fields like laser micromachining, multi-axis turning and milling services, and CNC graphite mold fabrication to support integrated solutions for demanding industries.

Gear Manufacturing: Precision at the Core

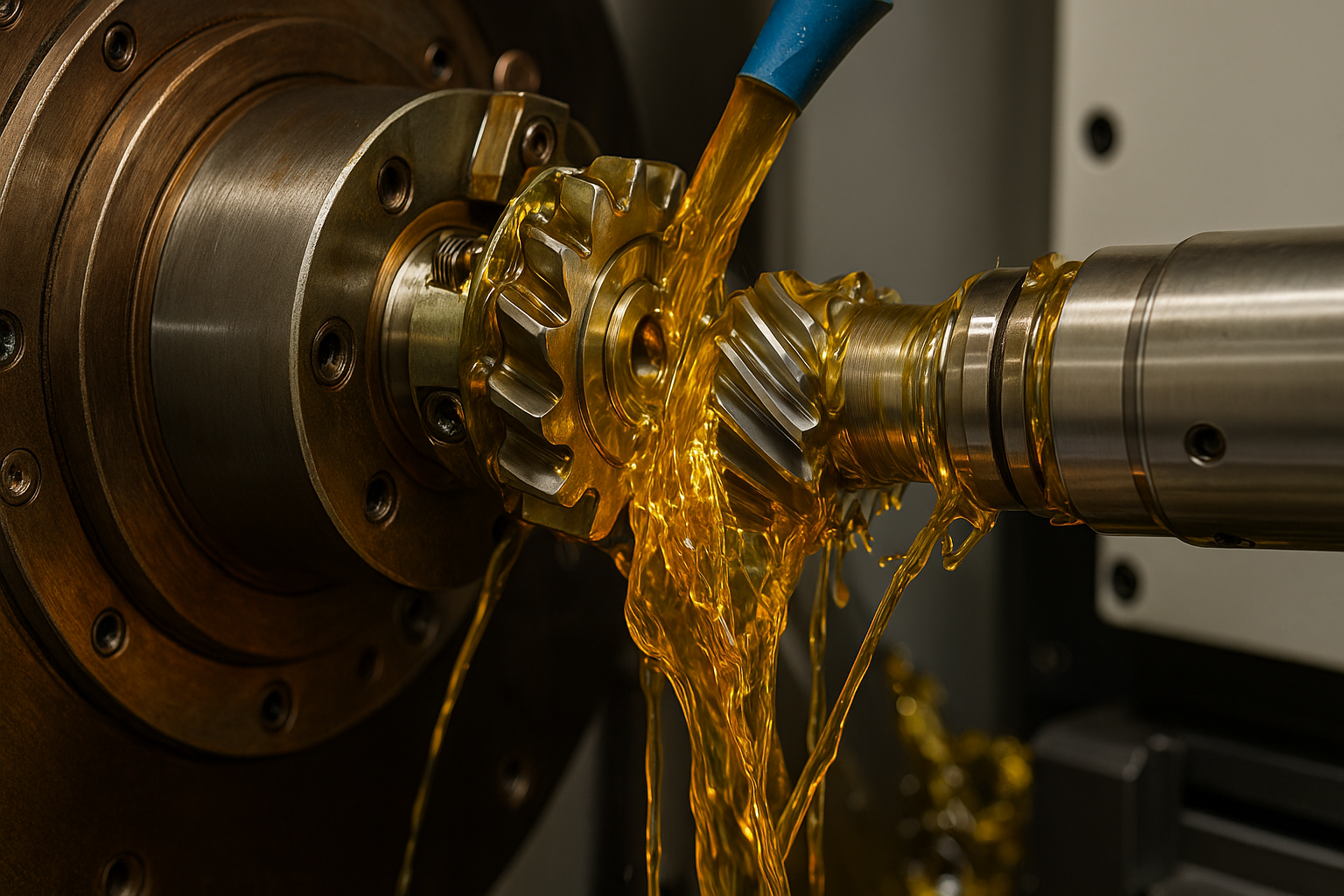

We specialize in the production of custom metal gears—spur, helical, bevel, and worm—ranging from 0.3 module micro gears to M8 industrial-grade units. Our CNC gear hobbing and grinding machines support:

-

Pitch diameter: 1 mm – 500 mm

-

Module range: 0.2 – 8

-

Tooth profile tolerance: up to DIN 6

-

Surface finish: Ra ≤ 0.4 μm (post-grinding)

-

Material compatibility: carbon steel, alloy steel, stainless steel, brass, PEEK

With in-house heat treatment and inspection via CNC CMM and gear analyzers, we ensure optimal backlash control and uniform torque transmission for aerospace actuators, robotics joints, and instrumentation.

Laser Micromachining: Sub-Micron Precision for Complex Features

For high-value applications such as micro gear modifications, lubrication hole drilling, or laser deburring, we use laser micromachining systems capable of:

-

Feature size: down to 10 μm

-

Positioning accuracy: ±1 μm

-

Materials: hardened steel, ceramic, titanium alloys, coated surfaces

-

Applications: micro texturing, gear marking, thin-slot creation, edge chamfering

This non-contact process avoids mechanical stress and is ideal for modifying gear profiles post-heat-treatment or working with fragile components.

Multi-Axis Turning and Milling Services: Complete Structural Support

Our turning and milling services cover the full spectrum of gear-related parts, from shafts and spacers to housing structures and keyed components. Capabilities include:

-

Turning:

-

Max OD: 300 mm

-

Length: up to 600 mm

-

Concentricity: ≤ 5 μm

-

-

Milling:

-

3-axis to 5-axis CNC

-

Machining envelope: up to 1000 × 600 × 500 mm

-

Surface finish: Ra ≤ 0.8 μm

-

Tolerance: ±0.01 mm standard; ±0.005 mm optional

-

We routinely machine stainless steel (304, 316), aluminum (6061-T6, 7075), tool steel (H13, S7), and engineering plastics like POM and PEEK.

CNC Graphite Mold Fabrication: High Precision EDM & Vacuum Mold Solutions

For clients in EDM machining, mold making, and semiconductor applications, we provide CNC graphite mold services using fine-grain isostatic graphite (grain size ≤ 5 μm). Our graphite machining systems support:

-

Dimensional accuracy: ±0.01 mm

-

Surface finish: Ra 0.4–0.8 μm (machined), Ra ≤ 0.2 μm (polished)

-

Electrode wear optimization: shape-tuned for reduced erosion

-

Typical applications: injection mold cavities, EDM sinker electrodes, high-temp tool fixtures

We also offer post-processing: degassing, polishing, and anti-oxidation coating for extended mold life.

Why It Matters: Precision Without Compromise

A single misalignment in a 0.5 module gear or micron deviation in an EDM electrode can cause cumulative failures. That’s why our gear machine shop integrates laser, turning, and graphite machining into a cohesive system—with unified QC, CAD/CAM programming, and material traceability.

Need prototypes within 3 days? Or production runs with CPK ≥ 1.67? We’re built to deliver.

Share:

Precision Carbon Fiber CNC Machining and Cutting Services

Casting vs Machining: Which One to Choose?