When customers evaluate a supplier, they rarely ask how many machines are on the shop floor.

What they really want to understand is manufacturing capability — whether a factory can turn drawings into qualified parts, repeatedly and predictably.

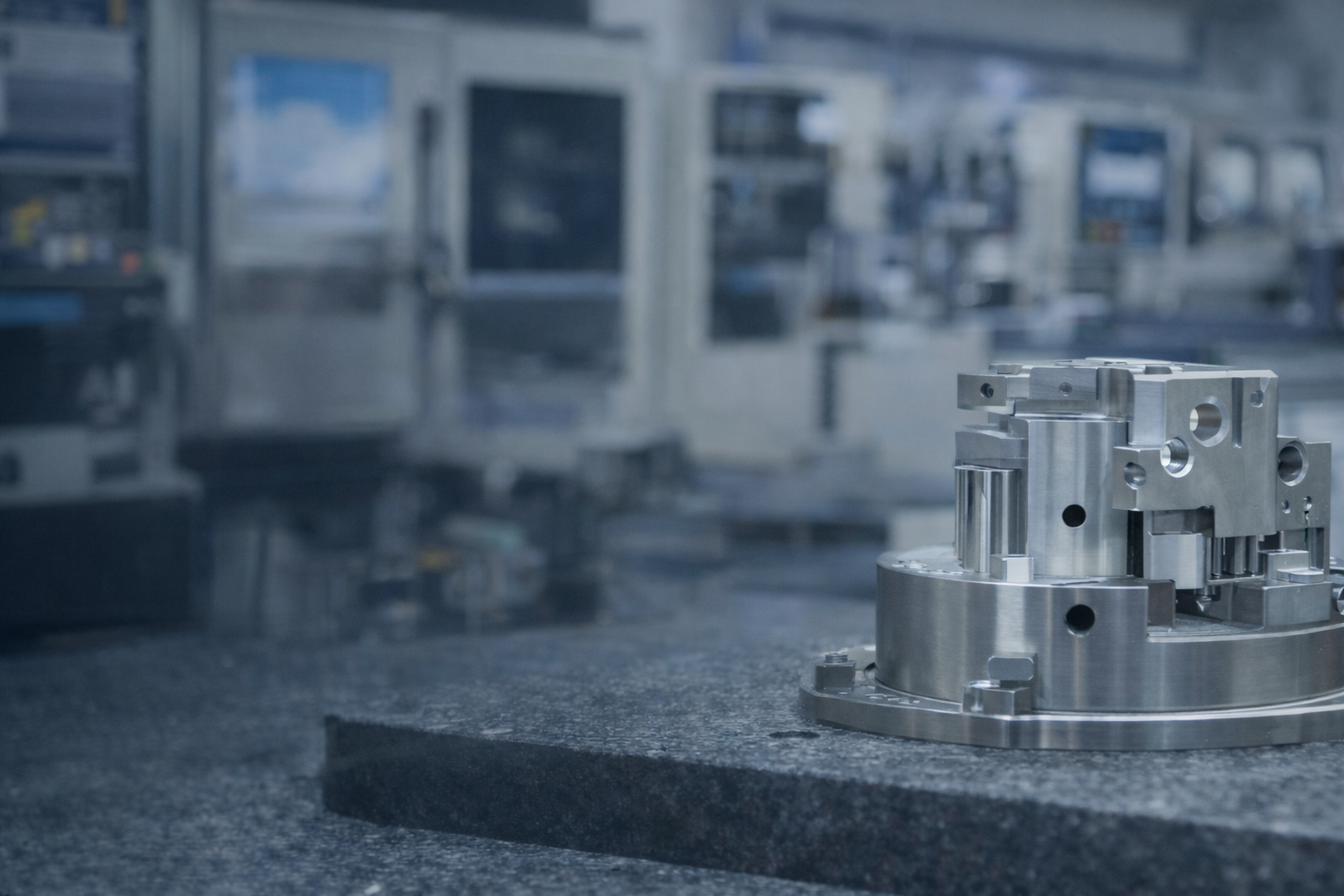

At XY-GLOBAL, manufacturing capability is defined by how projects are executed in real conditions. Instead of relying on a single workshop, we work with several long-term cooperating factories that have been collaborating for many years. This structure allows different processes to work together under stable control, forming a manufacturing capability that supports complex and multi-stage projects.

|

No. |

Machine |

Brand |

QTY |

Specification |

|

1 |

CNC Machining center |

DMG |

16 |

0.002-0.005 |

|

2 |

CNC Machining center |

Mazak |

16 |

0.002-0.005 |

|

3 |

CNC lathe |

DMG |

7 |

0.002-0.005 |

|

4 |

Flat grinder |

Taiwan |

3 |

0.001 |

|

5 |

Wire EDM |

Taiwan |

2 |

0.05 |

|

6 |

Die Casting Machine |

ZITAI |

1 |

2000 Tons |

|

7 |

Die Casting Machine |

LK |

1 |

1250 Tons |

|

8 |

Die Casting Machine |

ZITAI |

2 |

800~900 Tons |

|

9 |

Aluminum Extrusion Line |

Taiwan |

5 |

800~1800 Tons |

How We Define Manufacturing Capability

Manufacturing capability is not a single machine or process.

It is the ability to coordinate materials, processes, accuracy, inspection, and delivery into one stable workflow.

For our team, manufacturing capability means:

-

Parts can be produced according to drawings, not assumptions

-

Critical features can be controlled consistently

-

Different processes can connect without quality loss

-

Production remains stable from prototype to batch orders

This definition guides how we build and maintain our manufacturing capability every day.

Core Processes Supporting Our Manufacturing Capability

Our manufacturing capability is supported by multiple production processes that work together rather than independently.

-

CNC machining for precision metal parts and tight-tolerance features

-

Die casting for aluminum structural components requiring strength and consistency

-

Injection molding for plastic and engineering material parts

-

Aluminum extrusion for long profiles and structural sections

-

Sheet metal fabrication and assembly for frames, enclosures, and integrated parts

These processes are often combined in one project. By reducing supplier handover between steps, our manufacturing capability helps minimize variation and shorten lead time.

Production Scale and Size Range

A practical manufacturing capability must cover both small precision parts and large structural components.

To help customers quickly determine whether their parts fit our range, the table below outlines typical production limits across different processes.

| Manufacturing Process | Typical Maximum Size | Typical Minimum Feature |

|---|---|---|

| Aluminum Extrusion | Profile length up to 6,000–7,000 mm; cross-section ≤ 250 mm | Wall thickness 0.6–1.0 mm |

| MIM (Metal Injection Molding) | 150 × 100 × 35 mm | Feature size down to 0.1 mm |

| Sheet Metal | 2500 × 1000 × 6 mm | Structural dimensions ≥ 1.0 mm |

| Die Casting | Flat parts up to 900 × 900 mm; part weight under 10 kg | Thinnest section around 1.0 mm |

| CNC Machining | 850 × 550 × 1000 mm | Feature size down to 0.2 mm |

| Injection Molding | 1000 × 1000 × 400 mm | Wall thickness down to 0.1 mm |

This range is an important part of our manufacturing capability, allowing flexibility across different industries and applications.

Precision Control as a Key Part of Manufacturing Capability

Accuracy is a measurable indicator of manufacturing capability, especially for parts with functional or assembly-critical features.

Machining Accuracy: 2 μm

This level of accuracy is applied where it directly affects function, fit, and performance. Maintaining this accuracy requires stable processes, controlled tooling, and consistent inspection, all of which are integrated into our manufacturing capability.

Precision Machining Accuracy Reference

Precision Machining Accuracy Reference

Inspection Integrated into Manufacturing Capability

Inspection is not treated as a final checkpoint. It is part of our manufacturing capability from the beginning of production.

Coordinate measuring machines, optical projectors, and microscope inspection tools are used to verify dimensions, profiles, and surface conditions according to drawings. By identifying deviations early, the manufacturing capability remains stable even as production volume increases.

This approach is especially important for repeat orders and projects with tight tolerance requirements.

Manufacturing Capability Across Multiple Factories

Our manufacturing capability is strengthened by long-term cooperation with multiple factories rather than short-term outsourcing. These factories work together regularly, follow consistent quality standards, and support each other across different processes.

This structure allows our manufacturing capability to scale while remaining controllable, even for projects that require CNC machining, forming, and assembly in one workflow.

What Manufacturing Capability Means for Your Project

For customers, manufacturing capability directly affects project risk.

A coordinated manufacturing capability means:

-

Fewer unexpected changes during production

-

Reduced rework during assembly

-

More predictable delivery schedules

-

Less time spent managing multiple suppliers

Instead of evaluating each process separately, customers can rely on one manufacturing capability that supports the entire project lifecycle.

Final Perspective on Manufacturing Capability

Every project has different requirements, but manufacturing capability should always be clear, measurable, and proven through execution.

If you have a part with specific size, tolerance, or process requirements, sharing the drawing is the fastest way to evaluate whether it fits within our manufacturing capability and production range.

Share:

Case Study 18丨The 0.8 mm Hole — A Precision CNC Machining Service Storyontrol make the difference in precision CNC machining service.

Case Studies Parts 19 丨When Material Choice Matters: A Ceramic Manufacturing Case Study