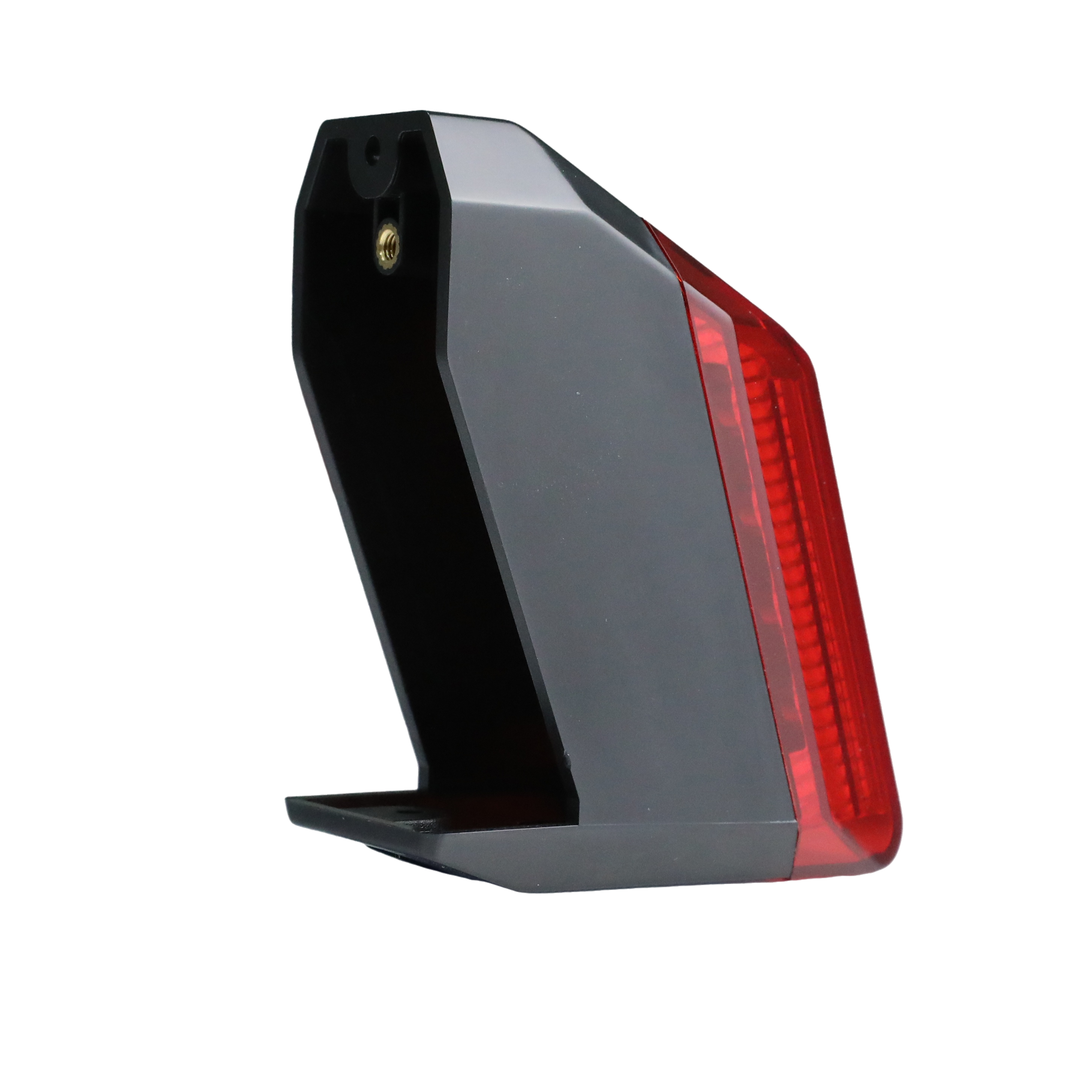

Precision Manufacturing Case: Bike Tail Light Housing

Combination of precision injection molding and structural parts processing

The housing of this bicycle taillight is injection molded with high-strength engineering plastics (such as PC+ABS), combined with highly transparent optical-grade PMMA lenses, to ensure that the overall structure is lightweight and impact-resistant, while ensuring that the light refraction is clear and natural. Every detail size is strictly controlled to meet the tolerance requirements of ±0.02mm, achieving a perfect unity of appearance and functionality.

1. Complex Curved Design & High-Gloss Finish

The tail light cover features multi-surface transitions and sharp contours, requiring extremely high precision in mold design and machining. The transparent lens undergoes fine polishing to achieve a surface roughness of Ra≤0.05μm, ensuring excellent light transmission and a premium mirror finish.

2. High-Precision Assembly & Dimensional Control

The housing, optical components, and electronic modules are assembled with a tolerance control of ±0.05mm, preventing looseness, leakage, and vibration. Strict dimensional inspection ensures batch consistency and product reliability.

3. Advanced Surface Treatments

The black housing adopts a durable matte spray finish, providing scratch resistance and UV protection. The red transparent lens is treated with an optical coating to enhance scratch resistance and anti-fingerprint performance, suitable for long-term outdoor use.

4. Full-Service Manufacturing Support

From DFM optimization and mold development to prototype production and small-batch manufacturing, we offer one-stop precision manufacturing services. This project showcases our strengths in multi-material molding, high-precision machining, and batch consistency management for consumer electronics, smart mobility equipment, and outdoor devices.

We’re here to help! From Free Prototypes to NPI Expert guidance, our team is dedicated to supporting your CNC machining and die casting needs with precision and care. Contact us anytime for assistance!

-

WhatsApp/Phone/Email