In cutting-edge manufacturing, 0 tolerance CNC machining represents the gold standard — where precision reaches sub-micron levels, and even the slightest deviation is unacceptable. This requires more than traditional CNC processes. As industries evolve toward sub micron machining, ultra precision diamond turning is emerging as the definitive method to bridge the gap between design perfection and real-world production.At XY-Global, we specialize in ultra precision machining and sub-micron diamond turning for industries requiring true 0 tolerance performance.

What Does “0 Tolerance” Really Mean in CNC?

Despite the term, 0 tolerance doesn't imply absolute zero deviation — but rather tolerances within ±1μm or better. This level of micro machining precision is essential in fields like:

-

Optics: for lenses and mirrors with near-perfect surfaces

-

Aerospace: where tiny alignment errors can lead to system failure

-

Medical devices: demanding flawless fits and surface smoothness

-

Semiconductors: requiring nanometer-level flatness and stability

Such requirements push beyond the limits of standard fine machining — demanding ultra precision solutions.

These industries face common challenges such as surface form accuracy, assembly misalignment, optical scattering, and tolerance stacking — all of which demand machining capabilities beyond conventional CNC methods.

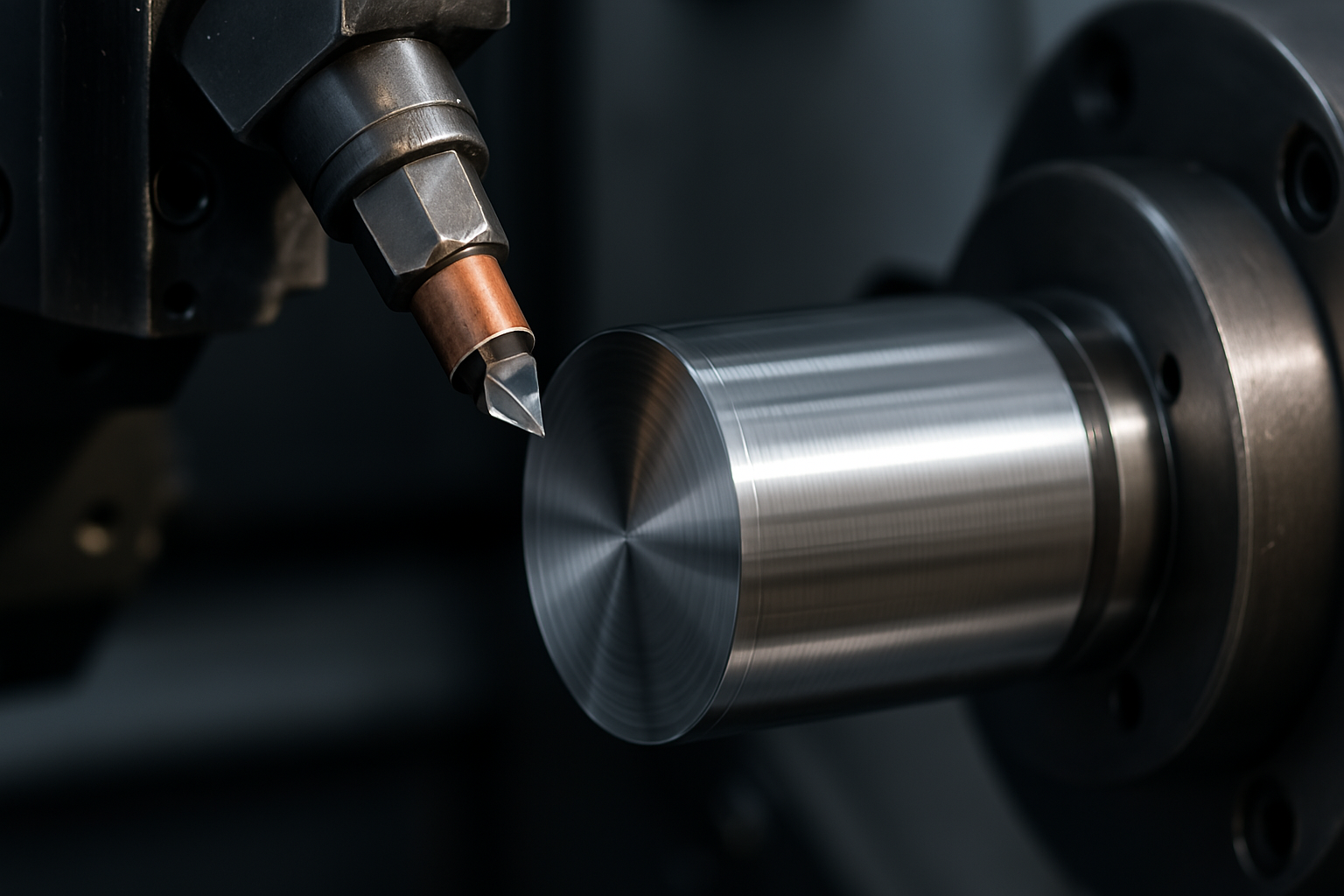

Why Ultra Precision Diamond Turning Is a Game-Changer

Ultra precision diamond turning uses single-crystal diamond tools on highly stabilized CNC platforms with nanometer-level motion control. It delivers unparalleled sub micron machining accuracy and ultra-smooth finishes, transforming the possibilities of fine machining.

Key Advantages:

-

🧭 Sub-micron accuracy (±0.1 μm) in dimensional control

-

🌊 Mirror-finish surfaces (Ra ≤ 0.005 μm)

-

⚙️ One-pass finalization, reducing the need for post-processing

-

🧱 Handles hard or brittle materials like optical glass, beryllium, PMMA

-

🎯 Eliminates cumulative tolerance stack-up in complex assemblies

This makes it indispensable for next-generation 0 tolerance CNC machining.

At XY-Global, our diamond turning platforms deliver ±0.1 μm dimensional accuracy, Ra 0.005 μm surface roughness, and repeatability within 0.2 μm under controlled temperature environments. We support freeform optics, aspherical lenses, aluminum mirrors, PMMA, and other optical-grade materials.

🔧 From Rough Cuts to Sub-Micron Precision: The Process Breakdown

| Stage | Technology Used | Precision Contribution |

|---|---|---|

| Rough Machining | CNC milling or turning | Initial shaping, removes bulk deviations |

| Semi-Finishing | High-precision CNC | Brings tolerance to within ±2μm |

| Diamond Turning | Ultra precision lathe + diamond tool | Final pass: sub-micron surface and dimensional finish |

| Real-Time Inspection | Laser or white-light interferometry | Closed-loop corrections during machining |

| Optional Finishing | Coating, stress relief, fine polishing | Enhances durability, aesthetics, and tolerance stability |

To maintain sub-micron consistency, XY-Global uses white-light interferometry, laser scanning profilometry, and CMM verification. These real-time feedback systems ensure every part meets optical-grade flatness and form accuracy requirements.

Application Highlights: Where Precision Is Everything

| Industry | Component | Tolerance Requirements |

|---|---|---|

| Optics | Aspherical lenses, mirrors | Form error < 0.1 μm, Ra < 0.01 μm |

| Aerospace | Navigation components, gyroscope parts | < ±0.002 mm concentricity |

| Medical | Microsurgical tools, optical housings | No visible deviation, hermetic fit |

| Semiconductor | Wafer stages, chucks | Nanometer-level flatness, absolute alignment accuracy |

These are the areas where XY-Global actively supplies micro-machined components, helping clients achieve stable, repeatable performance at sub-micron tolerance levels.

These sectors rely heavily on ultra precision diamond turning for consistent micro machining at extreme tolerances.

Why Only Ultra Precision Techniques Deliver True 0 Tolerance CNC

Even the most advanced CNC machines have limits. Only diamond turning, with its nanometric resolution and direct-to-surface cutting ability, can consistently achieve:

Our Ultra Precision Services Include:

-

Diamond turning of metals & optical polymers

-

Freeform and aspherical surface machining

-

Optical mirror finishing

-

Prototype-to-mass production support

-

DFM optimization for ultra precision parts

-

✨ Freeform surfaces with ultra-low form error

-

♻️ Repeatable sub micron machining

-

🏁 Direct-to-assembly finishes that require no further adjustments

This synergy of precision and efficiency defines the essence of fine machining at the 0 tolerance level.

If your project requires ultra precision machining or sub-micron diamond turning, our engineering team can support both prototype and volume production. We help clients achieve optical-grade accuracy and 0-tolerance assemblies across diverse industries.

Conclusion

Ultra precision diamond turning is not just an upgrade — it’s the enabler of true 0 tolerance CNC machining. By pushing the limits of micro machining and delivering nanometer-grade finishes, it ensures:

✔ Absolute accuracy

✔ Mirror-like surfaces

✔ Seamless integration from machining to assembly

For industries where "almost perfect" isn't good enough, ultra precision techniques are the only way to meet — and exceed — modern manufacturing standards.

Share:

Inside Laser Optics Assembly: How ±0.005 mm Machining Keeps Your Laser on Target

High Pressure Die Casting Services for Reliable Mass Production